|

|

Post by mark on Apr 30, 2014 7:43:04 GMT -5

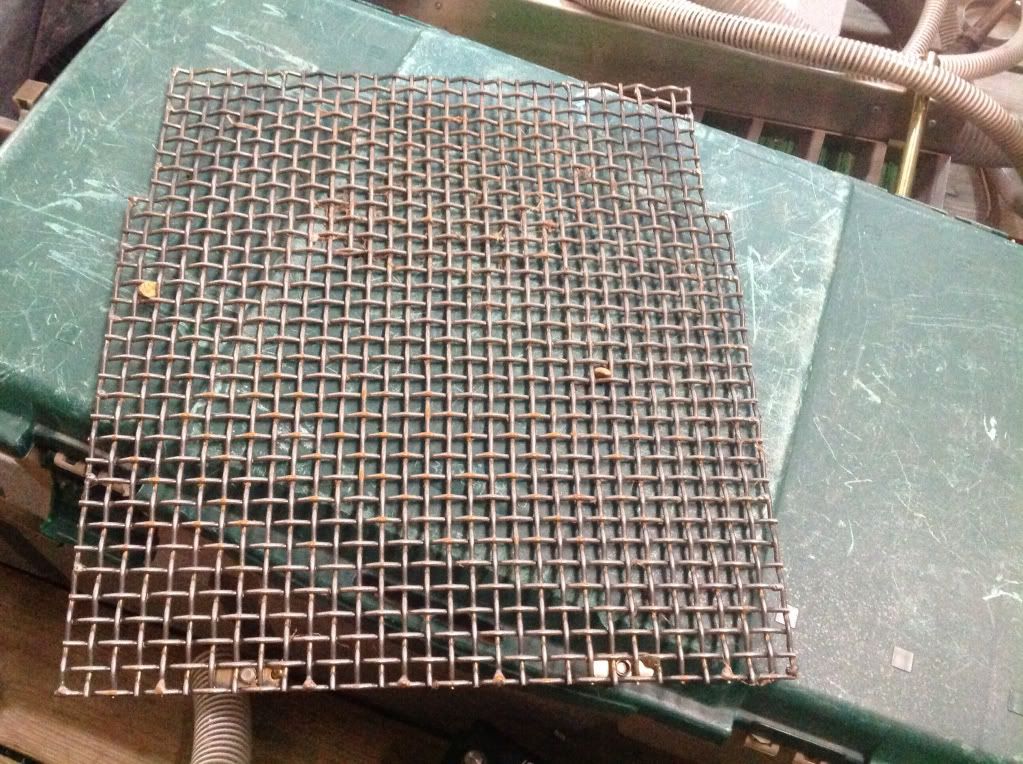

Does anyone know where I can get some more of this? I want to extend it all of the way through my sluice, where now it stops about 1/3 rd of the way down.  |

|

|

|

Post by mark on Apr 30, 2014 10:22:26 GMT -5

You know I thought about that, but i would love to keep those bigger pebbles completely out of my riffles. Pat Keene told me I needed to be running my dredge at about 90% anyway  |

|

|

|

Woven wire

Apr 30, 2014 10:26:11 GMT -5

via mobile

Post by ywevis on Apr 30, 2014 10:26:11 GMT -5

Did you ask about the woven wire to pat as well?

|

|

|

|

Post by mark on Apr 30, 2014 12:41:10 GMT -5

That was what I was told also. I guess out west they don't care about catching the little stuff as much as we do. We don't seem to have the big stuff as abundant as they do. When 95%+ of your gold will go through a 20 mesh classifier your best to figure out how to catch it and running your motor at 90% isn't going to do it! Agree 100% on that! I catch a lot more fine gold that other dredges, so I guess I should just leave it alone. |

|

|

|

Post by loki258 on May 1, 2014 6:33:34 GMT -5

Too true.

|

|

|

|

Post by cabarrusgold on May 1, 2014 7:05:26 GMT -5

I tried something close to that and found it kept the water too turbulent. Small AU could be suspended with all the air created by the turbulence. However, I did enjoy the classifying effect.

|

|

|

|

Post by jpgold on May 1, 2014 20:26:34 GMT -5

I agree with kevnc. Keene Proline Gold Grabber wouldn't exist if their sluices didn't work. They spend a lot in R&D so they better work reliable and effectively. However Marks idea should be researched. At worst it would suck. At best it would work really well. Maybe not in a triple sluice but an over under it might be just the ticket. A test mule needs to be constructed. Then Mark can make the American dredgers company and sell it. Lol. Good luck Mark. Kevnc I have been push to change my Proline but i don't think i will.

|

|

|

|

Post by jpgold on May 2, 2014 18:39:45 GMT -5

James told me to slow it down when I was dredging and it seemed to work.

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on May 3, 2014 5:52:20 GMT -5

Putting ribbed matting under the miners moss will cause it not to exchange properly. It also changes how much the moss is compressed.

I put a small piece at the end of the sluice but if the riffles are set right you really don't need it. The riffles are suppose to clamp down tight enough to prevent migration. Wes

|

|

|

|

Post by ywevis on May 3, 2014 8:20:37 GMT -5

Putting ribbed matting under the miners moss will cause it not to exchange properly. It also changes how much the moss is compressed. I put a small piece at the end of the sluice but if the riffles are set right you really don't need it. The riffles are suppose to clamp down tight enough to prevent migration. Wes He needs to know how fast to run his proline 3 inch, I think he might be running it to fast. |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on May 3, 2014 18:55:19 GMT -5

Set the sluice in the neutral position, run it and get some material in the sluice and then check it like Kev is saying.

Run the engine about 1/2 throttle if you are shallow, the deeper you are dredging the more engine speed you will need.

Don't try to clear all 3'' rocks out of the sluice by changing the engine speed and/or the angle of the sluice.

Just because you have a 3'' dredge doesn't mean you should run all the 3'' rocks thru your dredge.

Set your dredge where it will clear 1'' rocks and then throw as many larger rocks out of your hole as you can.

No dredge is capable of discharging large material and holding fine material at the same setting. IMHO Wes

|

|

|

|

Post by jpgold on May 3, 2014 19:49:49 GMT -5

Thanks guys for info. Hoping soon we can get together and y'all can show me a good set up for the dredge.

|

|

Don

New Member

Posts: 2

|

Post by Don on May 4, 2014 8:58:28 GMT -5

back to the original ? the mesh you was interested in is the same as used on the rock crusher in most quarries to classify material. they are stacked in sizes mostly from 5 inch sq to 1/2 inch sq to get the diff grades of rock. or thats what I have seen when I have to go work on this stuff. sometimes you can find it at the scrap yards if they have a break in it, and the 1/2 size breaks pretty often.

|

|

|

|

Post by sanman on May 11, 2014 20:15:12 GMT -5

|

|

|

|

Woven wire

May 11, 2014 20:54:58 GMT -5

via mobile

Post by ridgeline on May 11, 2014 20:54:58 GMT -5

I have a 4 inch proline and i find alot of fine gold i run it wide open all the time and only adjust the angle depending on material i have found fine gold behind a keene lol

|

|