|

|

Post by cabarrusgold on May 22, 2014 19:18:07 GMT -5

Thought this may help someone out.

|

|

|

|

Post by indyme2 on May 22, 2014 20:03:22 GMT -5

If you pull the head, you may as well pull the other plate, replace the gasket and reed valves too as a minimum. Thanks for the post.

|

|

|

|

Post by Gold Seeker on May 23, 2014 5:11:11 GMT -5

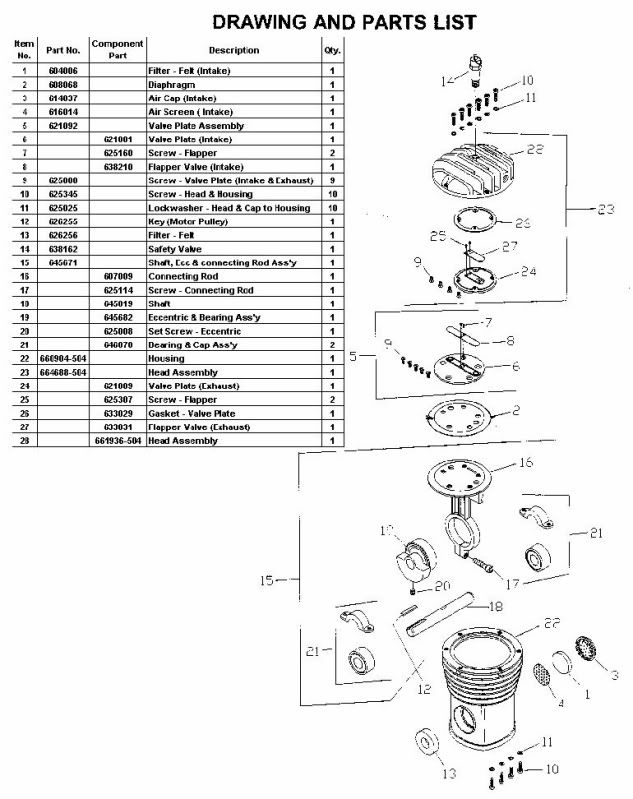

Here's an exploded diagram and parts list of the T-80 that will help as well. Right click on the image and save it to your computer.  |

|

|

|

Post by cabarrusgold on May 23, 2014 5:43:23 GMT -5

Wonder what it would be to replace all? Keene?

|

|

|

|

Post by cabarrusgold on May 23, 2014 6:17:18 GMT -5

I have been having problems with enough air for awhile. Thought it was mask. Then the damn belt went. Think I have belt corrected with an adjustment plate on air compressor. But... what if my real problem is the pump itself? I bought that dredge used. Have no idea how hard they ran it. Even without air the pump is still running. I guess I need a gauge somewhere.

|

|

|

|

Post by Gold Seeker on May 23, 2014 15:53:44 GMT -5

I have been having problems with enough air for awhile. Thought it was mask. Then the damn belt went. Think I have belt corrected with an adjustment plate on air compressor. But... what if my real problem is the pump itself? I bought that dredge used. Have no idea how hard they ran it. Even without air the pump is still running. I guess I need a gauge somewhere. If the compressor is not putting out enough air it's usually the reed/flapper valves not closing properly, a quick fix if the valves seem to be in decent condition is to flip them over, sometimes they will get bend upwards after prolong use. Another sure for getting more air it too put a smaller pulley on the compressor to get more RPMs out of the compressor If the compressor is old and has never been opened up, I would overhaul it, if the bearings seems to be fine it's not that expensive to replace the diaphragm, reed/flapper valve, gaskets, pop-off valve(if it not popping off when running) and filter, when you're finished you will have an almost new compressor, if you have to replace the bearings it get a little expensive, but still cheaper than a new compressor. |

|

|

|

Post by cabarrusgold on May 23, 2014 17:23:54 GMT -5

Great! I'll take a closer look.

|

|

|

|

Post by cabarrusgold on May 26, 2014 9:10:05 GMT -5

I had a 40+ micron filter installed on the system before holding tank and took it off. Now I understand that the P-180 produces very fine aluminum dust, so I will be installing it back soon. When I took off my P-180 to fix belt, I saw a lot of aluminum dust and other debris in the bottom of calendar. This is where the intake was and was not airborne material from snorkel. Yikes! Cleaned all that out the best I could and installed a rubber base on it to help secure and keep out unwanted particles. Now I need to take a look at top side to see if reed flappers are corroded via that dust issue. Don't want aluminum dust in my lungs. There are a bunch of dredges out there without filters installed. Check for that dust.  |

|

|

|

Post by Gold Seeker on May 26, 2014 10:48:22 GMT -5

"...I saw a lot of aluminum dust and other debris in the bottom of calendar..."

When you say "...calendar.." what exactly do you mean?

Did you mean to say cylinder, was this inside the compressor or under the unit, between it and the engine mounting plate?

|

|

|

|

Post by cabarrusgold on May 26, 2014 14:49:46 GMT -5

LOL... the spell check must have done that without me seeing it. Yes... under unit.

|

|

|

|

Post by Gold Seeker on May 26, 2014 15:05:10 GMT -5

OK, that rubber damper should stop the compressor from vibrating on the engine plate and causing the dust.

|

|

|

|

Post by cabarrusgold on May 26, 2014 16:14:16 GMT -5

Cool! I also made an adjust plate for it while I had it off. Should work great.

|

|

|

|

Post by cabarrusgold on May 26, 2014 16:15:17 GMT -5

OK, that rubber damper should stop the compressor from vibrating on the engine plate and causing the dust. Thanks for the help... |

|

|

|

Post by cabarrusgold on Jun 7, 2014 6:43:46 GMT -5

Changed out diaphragm yesterday and cleaned reed. Wow... wore out and dirty. Noticed in schematic that it has an exhaust reed as well. Guess, I need to take it apart again and check that for dirt! When I removed the screws from intake plate, I did not know how to get plate off rubber. So... just pry with screwdriver and it will pop off. I guess the heat caused it to bond with the metal. It was almost like it was glued on.

|

|

|

|

Post by indyme2 on Jun 7, 2014 7:06:32 GMT -5

There are two reeds, cabarrusgold. The other is on the underside. Only takes a few minutes to change both once you pull the head. |

|